Optimizing E. coli cell growth performance with in-line, real-time OD600 (abs/mm) monitoring during the fermentation process

Cell & Gene Therapy Insights 2022; 8(8), 827–834

DOI: 10.18609/cgti.2022.114

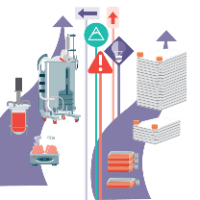

The increasing demand for cell and gene therapies (CGT) has created a need to optimize manufacturing process steps using Process Analytical Technologies (PAT) to lower costs and increase yields. Plasmid DNA (pDNA) is a precursor to the development of CGTs and is met with many challenges throughout the production process due its size, viscosity, and similarities to other impurities. The generation of these plasmids in high density E. coli cultures can be difficult to monitor using traditional off-line OD600 methods due to the careful sample preparation, fast growth rate, and dilutions required to be in the linear range of a standard spectrophotometer. This study proposes utilizing an in-line, variable pathlength spectrophotometer in a recirculation loop during fermentation to monitor and optimize the growth of E. coli cells in real-time. This provides distinct advantages over traditional methods due to the constant modification of path lengths to create a slope-based solution that is always within the linear range of the equipment, with no buffer correction required. The growth curve is tracked in real-time using the slope (Abs/mm) at 600 nm to measure cell density and to optimize growth performance of cells. This will serve as a proof-of-concept for the optimal cultivation of E. coli and production of pDNA. The Biofactory Competence Center (BCC) is a not-for-profit organization based in Switzerland with the aim of providing training courses to the biopharmaceutical industry and related sectors, in order to supply a highly trained workforce. The BCC also provides technical services, including process design, development, and optimization.