A scalable lentiviral vector production system based on stable producer cell lines

Currently, the manufacture of clinical-grade LVV is still based on transient transfection of plasmids to 293T cells which caused lots of challenges. EurekaBio has developed the EuLV system, a scalable lentiviral vector production system based on stable producer cell lines. This stable producer cell line no longer requires transient plasmid transfection; instead, all the required packaging genes (such as VSV-G, rev, gag/pol), as well as the customized therapeutic genes or commonly called gene of interest GOI, are stably inserted into the genome of the producer cell lines, and the production of lentivirus is simply achieved by chemical induction. This system is adapted to high cell density suspension culture in the chemically defined medium. EuLV increases the expressing efficiency, improves the product quality and decreases the manufacturing cost.

- Difference between manufacture LVV using stable producer cell line and transient transfection

- Key data involved in packaging and producer cell line development

- 25L scale suspension manufacture process

- EuLV system's performance based on different GOI

You might also like

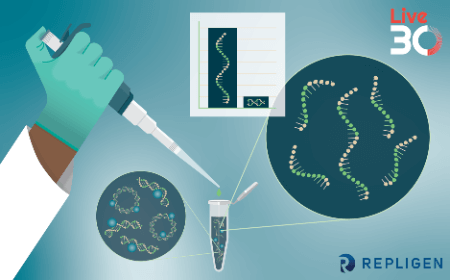

Scalable solutions for optimizing lentiviral vector production

Industrialization of AAV manufacturing with Xcite® transient and stable production platforms

Case study: establishing a versatile and intensified lentiviral vector production platform with TFDF

Innovative approaches to lentiviral vector purification: achieving high yields and purity with a chromatography-free process